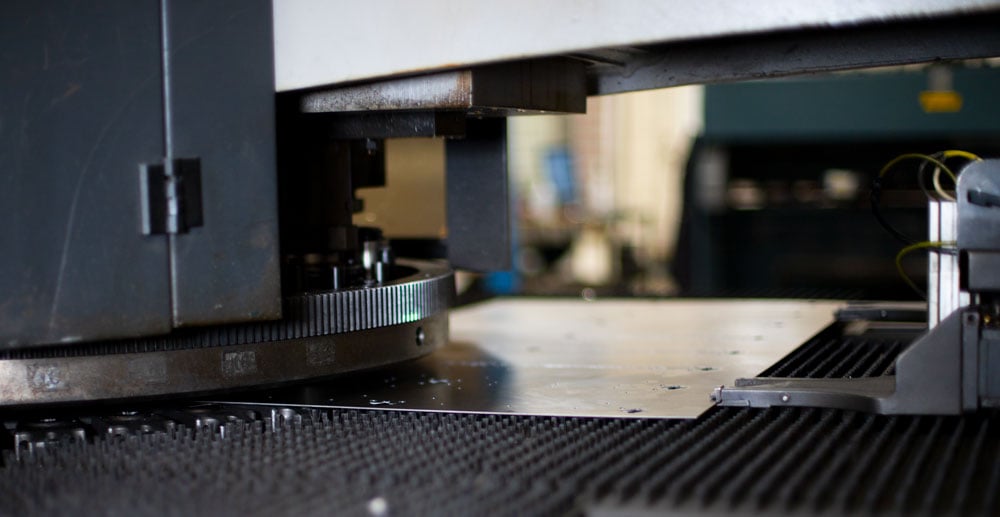

CNC punching, or sheet metal punching, is a metal manufacturing process that utilizes computer numerical control (CNC) technology. A CNC punch press locates the position of the sheet within to punch a hole with a ram or uses forming tools to add features such as dimples, lances or extrusions.

A programmer enters their 2D flat pattern into software such as SMP/IS. Then they will begin selecting tools from a library to produce the flat part using a combination of metal hole punching techniques, which creates the G-Code (or CNC code).

The uploaded code will determine which tools the CNC punch press will use at which locations. The operator will then load the correct tooling and calibrate the machine. After calibrating, the punch press will begin to read the code at an extremely high rate of speed to create the part.

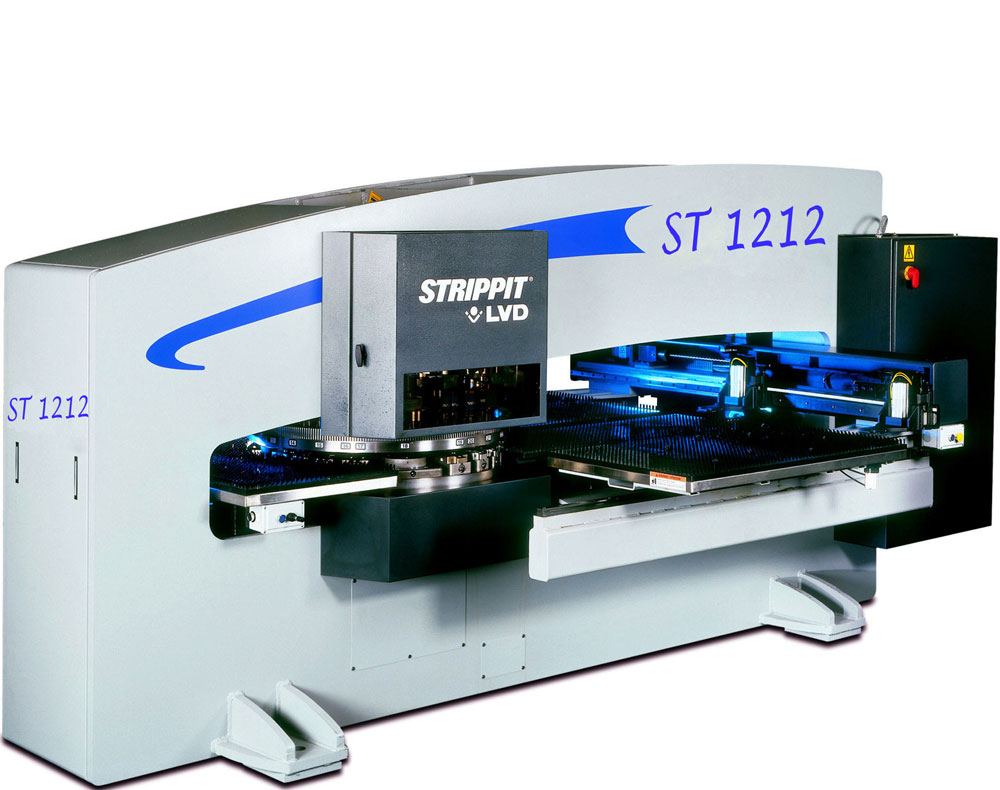

STATION | 26

MAX MATERIAL THICKNESS | 0.250˝

PUNCHING ACCURACY | ± 0.004˝

TONNAGE | 21 tons

NOMINAL WORKPIECE SIZE | 49.2˝ x 49.2˝

We have two LVD Strippit ST1212 CNC punch presses for metal punching. Intuitive nesting software allows us to nest multiple parts with the most efficient use of material to eliminate waste. We've also compiled a vast tooling library of shapes, specials, and forming tools to add as much value to your project as possible.