Structural metal is a manufactured form of metal other than sheets and is available in materials like mild steel, stainless steel, aluminum, copper, or brass.

Structural metals are usually more durable and well suited for infrastructure and complex components due to the force redistribution each form has. Commonly thought to only be used for heavy metal fabrication, structural metals are also part of metal fabricated parts and assemblies.

Common forms of structural metal include angles, bars, channels, extrusions, pipes, tubes, and strut channels.

When you think of structural materials in use, most people would picture large applications like construction and architecture, energy services, and other large industrial applications.

While those are a huge division of usage for structural steel and aluminum we’re seeing structural materials becoming instrumental in a multitude of industries. Like the stainless steel square tubing used within assemblies for canning solutions, or the aluminum piping inside truckmounts and cleaning solutions.

Adapter Plates

Drain Ports

Tank Braces

Pole Mounts

Pole Hooks

Spacers

Rotary Table Braces

Lift Housing Members

UV Rail Brackets

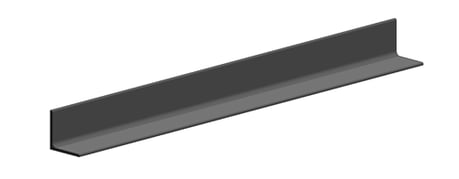

The angled form of structural metals is an L-shaped profile when the material is lying on its side. This shape provides added structural integrity or is often an additional piece used when repairing fabrication.

The bars available come in a few different forms, named after their side profile, are solid throughout (no openings). There are round bars, square bars, rectangular (flat) bars, and occasionally hexagonal bars. All variations offer an added stability when compared to sheets and are fabrication favourites.

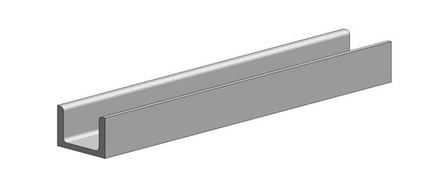

Manufacturers form metal channels specifically for industrial and structural builds. This form offers extra support from the U-shaped profile, while the opening allows for any water it comes in contact with to dry easily compared to tubes.

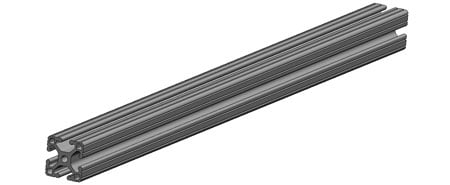

The unique profiles of extrusion (known as extrudates) result from the metal forming process, where machines push molten cylindrical bars of metal through an opening with the desired finished profile.The profiles can be highly complex and provide more structural support.

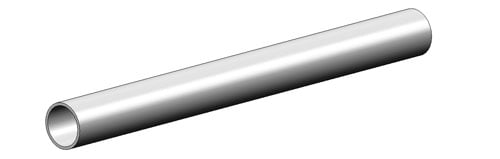

Businesses use metal pipes for the transference of gas or fluids (water, gas, or oil), their profiles are always round, and have larger sizes available than tubes. A pipe’s important feature is the inside (nominal) diameter, since something will flow through it, and the wall thickness (referred to for pipes as a “schedule”).

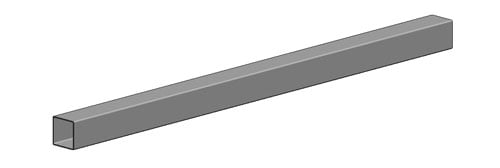

Metal tubing comes in square, rectangular, or round profiles. The purpose of tubing is to provide structural support, making the more important feature of it the exterior diameter and wall thickness.

This unique shape starts with the classic channel profile, with added curls on the ends to provide added structural support and grip. Commonly struts come with holes throughout the long back side of the channel, allowing the end-user or fabricators to more easily attach it to other parts. With hardware installed in the openings, it pulls in the curls on the opposite side, creating a tight assembly.