Laser cutting is a metal cutting service that uses a highly amplified and focused beam of light to cut material.

Lasers can cut much thicker materials and their superior ability for cutting complex geometries like curves, splines, and radii profiles with ease makes lasers a popular choice.

The machine uses a G-CODE to direct the laser and cut the pattern into the metal. The laser beam that is being used to cut the materials is created by an oscillator within the machine, which creates electricity.

In CO2 lasers this electricity is sent into a highly reflective resonating tube where it mixes with CO2, nitrogen, helium, and various other gases, and the beam of light is created. This beam is then sent through the resonator along a series of mirrors that amplify it. Finally the beam is sent down through a focusing lens where it mixes with the assist gases of the machine for optimized cutting, to a focal point at the workpiece.

In fiber lasers, the resonator tube, or bellow, is replaced by a fiber optic cable made from rare elements, the main being erbium. The beam itself is retained within the fiber, eliminating the need for optical mirrors through the resonator. This produces an efficient, constant beam at the cutting focal point.

POWER SOURCE | 4000 Watts

MAX MATERIAL THICKNESS | 0.875˝

LASER ACCURACY | ± 0.0002"

CUT TIME | 362"/minute

BED CAPACITY | 5' X 10'

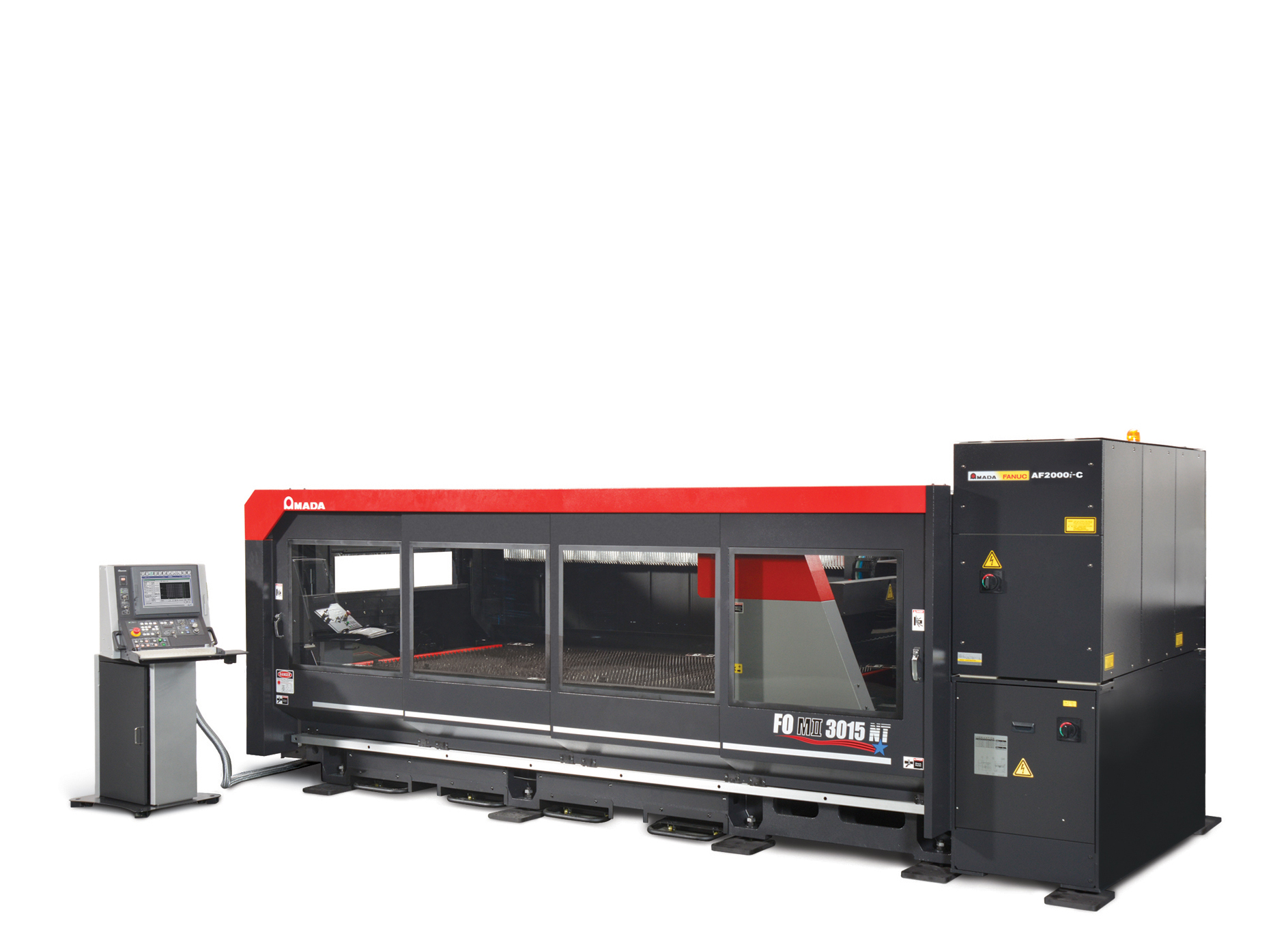

We are currently using an Amada FOM2-3015 NT CO2 laser for our precision laser cutting needs. This machine is capable of processing materials in thicknesses up to 0.875” (22.2mm) for mild steel, 0.375” (9.52mm) for aluminum, and 0.500” (12.7mm) for stainless steel laser cutting.